SMART BOLT TENSIONING

TAMPER PROOFED

Avoid risks.

Our bolt tensioning devices are controlled by our BT Control software.

The result is very evenly and precisely tensioned nuts and flanges. For each bolt, all forces actually acting are measured and documented in a tamper-proof manner – an important contribution to the safety of the overall construction.

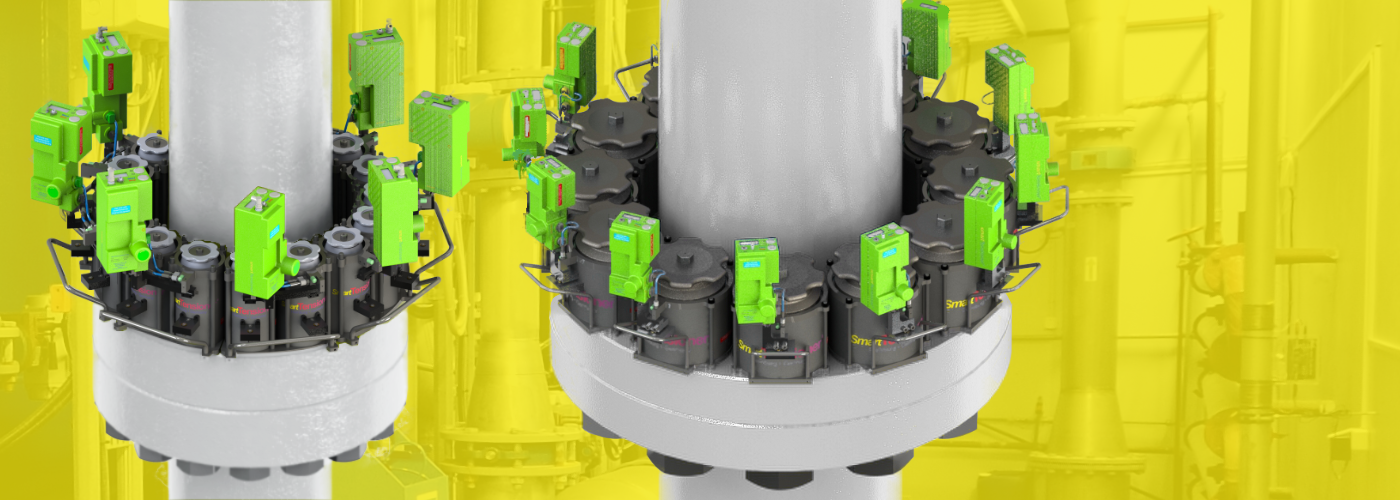

LEIGHTWEIGHT AND COMPACT

Low weight, compact design.

Our pumps are firmly connected to the bolt tensioning device and are therefore small and light. For typical requirements, the total weight and space consumption of our smart devices are e.g. in a wind power plant much less than with conventional solutions – with the decisive advantages, e.g. in construction, transport logistics and maintenance in industrial plants.

BOLT FORCE DETERMINATION

Precise Axial Forces.

The stud is only elongated – no nut turning is needed. Therefore the full load bearing capacity of the stud material can be used to withstand the axial stud forces. There is no shear stress because external torque applies.

Here is an example, how this works.

FAST SETUP TIME

Save construction time.

smartTensioner technology reduces the duration of the tensioning process: no hoses need to be connected, no high-pressure connectors need to be operated, no heavy pumps need to be transported. The combined weight of the devices that need to be transported to the installation site is significantly lower.

EASY TO USE SOFTWARE

Precise Control.

Multiple studs can be tensioned at the same time using our electronically synchronized and software driven pumps (HP). No setting losses appear and the targeted bolt force in every individual bolt can be exactly determined, measured and guaranteed.

Here you can have a look on our easy to use interface on a tablet pc.

USER SAFETY

Reduced risk of injury.

Conventional bolt tensioning requires one big and heavy hydraulic pump because all tensioning devices are hydraulically connected to each other and supplied by one pump. Our technology operates differently: our pumps are very small and light. Very small hydraulic volumes ensure overall operational safety. The risk of bursting hoses, leaking connectors or pistons that have moved too far is eliminated.